Rice husk pellet machine line biomass pelllet line

Rice husks are the husks of rice grains that are obtained from rice mills for rice processing. Rice husk has a high fiber content and is a good raw material for the production of granules. Rice husks usually obtained from rice mills are dry with around 14% moisture, which is the optimum moisture for pelletizing biofuels. Due to the small size of rice husks, it can be directly pressed into biofuel pellets by a pellet mill.

According to our experience of rice husk granulation, since rice husk contains some oil, granulation is easy, considering that the bulk density of rice husk is not high, pressing the rice husk into granules requires a ring die with a high compression ratio. We have many customers Rice husk granules are produced using our ring die granulator, they use a 1:5.8 compression ratio ring die to produce high quality granules.

Rice husk is the largest by-product of rice processing, accounting for 20% of rice by weight. Today, the world's annual output of rice is 568 million tons, and the world's annual output of rice husks is 11.36 million tons.

Rice husk is a waste produced during the refining and processing of rice, which has no commercial interest, low density and is not easy to transport. However, in industrial processing, where rice husk is regarded as a material with added value, there is a technological trend towards cost reduction and recycling.

Rice husk pellets have attracted widespread interest worldwide as an alternative energy source to the usual non-renewable fossil fuels. In Malaysia, one of the famous rice-growing countries, rice husk pellets can replace oil and coal to generate heat. For Vietnam, the world's second-largest rice exporter, rice husks have been a popular material for biofuel pellet processing. In fact, heating systems designed for the use of rice husk pellets are now widely available on the market in several countries around the world.

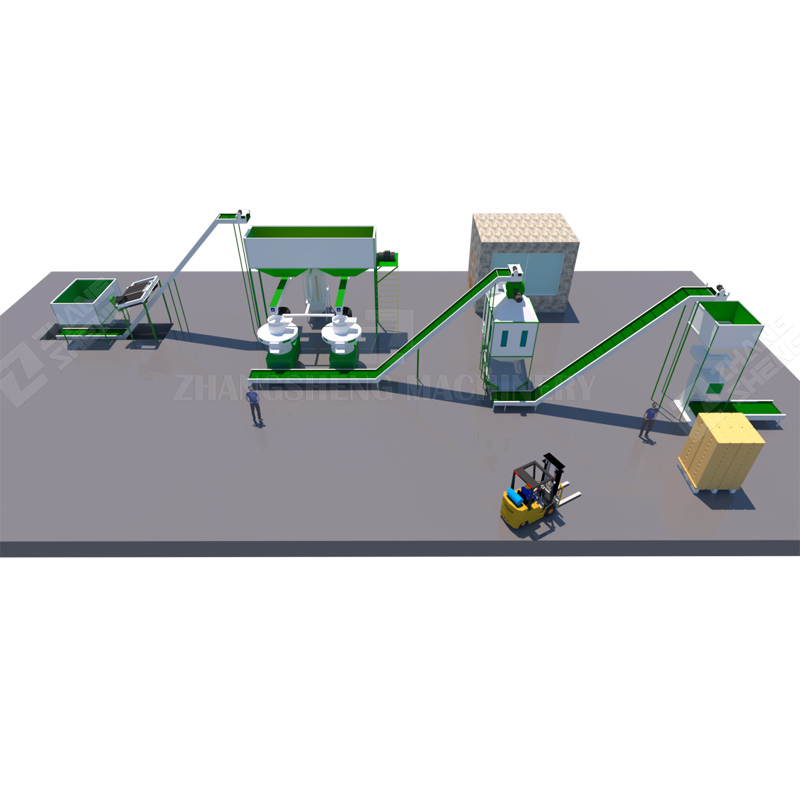

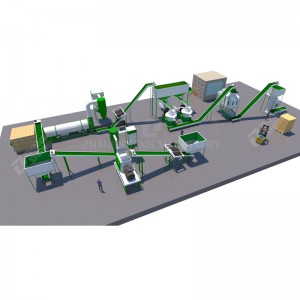

1. Zhangsheng Machinery has excellent technology and experience in rice husk granulation. We can provide both stand-alone rice husk pellet machines and turnkey project solutions for complete rice husk pellet production lines.

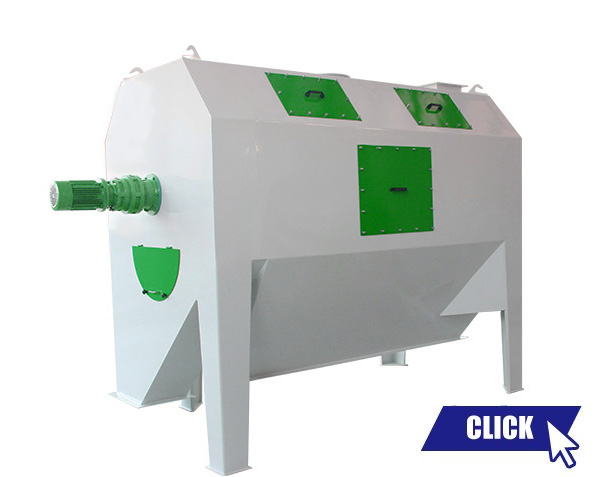

2. Our rice husk pellet machine adopts high-quality components, with stable performance, long service life and low noise.

3. We use advanced motor gear transmission system, which is stable and reliable..

4. The entire transmission components (including the motor) are made of high-quality SKF bearings to ensure efficient, stable and low-noise transmission. The main motor is Siemens.

5. We adopt international advanced technology: ring die manufacturing adopts German gun drill and vacuum furnace heating manufacturing process to ensure smooth and high-quality pallets.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

1. Are you a factory or a trading company?

We have our own factory. we have over 20 years of experience in the pellet line manufacturing. "Market our own products" reduces the cost of intermediate links. OEM available according to your raw materials and output.

2. Which raw materials can be made into biomass pellets? If any requirements?

Raw material ca be wood waste, logs, tree branch , straw, stalk, bamboo, etc including fiber.

But the material for directly making wood pellets is sawdust with a diameter of no more than 8mm and moisture content of 12%-20%.

so if your material is not Sawdust and moisture is more than 20%, you need other machines, such as wood crusher,wood hammer mill and dryer etc

3. I know very little about pellet production line, how to choose the most suitable machine?

Do not worry. We have helped a lot of beginners. Just tell us your raw material, your capacity (t/h) and the size of the final pellet product, we will choose the machine for you according to your specific situation. V

4. What is the use of rice husk pellet?

The traditional use of rice husks is to heat the drying air in rice dryers. The calorific value of rice husk pellets is greatly improved by the biomass fuel pellet line processing. Today, rice husk pellets are considered a biomass fuel resource and are increasingly used to fuel some co-fueled power plants.

5. What is the process of making pellets?

The process of making fuel pellets involves placing the pulverized biomass under high pressure and forcing it through circular openings called "dies." When exposed to the right conditions, biomass "fuses" together to form a solid mass.