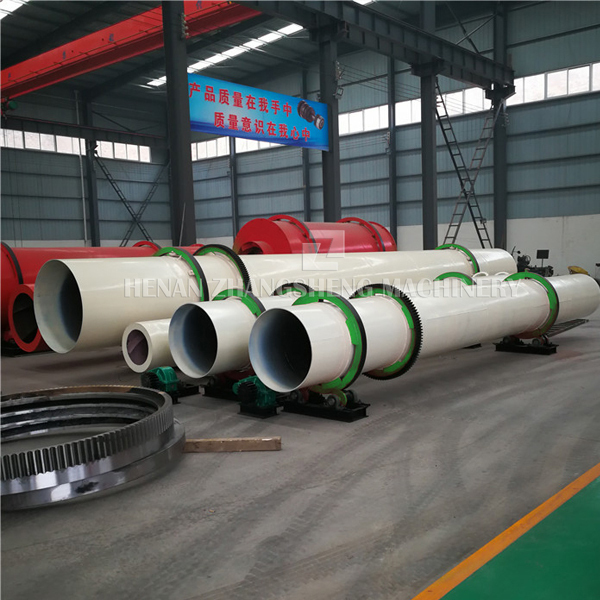

Industrial rotary dryer for biomass pellets

After the materials enter the cylinder through the loader, they are pushed to the lifting plate by the guide screw. Due to the tilt and rotation of the machine body, the materials are constantly lifted and scattered along the cylinder, and at the same time, they move longitudinally in the cylinder; The high-temperature flue gas is turned to the outer flue through the roller and tail pipe, and the material and high-temperature medium conduct heat exchange through heat conduction and thermal radiation, so that the moisture contained in the material is heated and evaporated, thus drying.

1.Fast processing speed, large processing capacity and low fuel consumption.

2. Low use cost, simple operation, protective device and safer use.

3.The supporting wheel and rolling ring are used in the shape design to make it more firm.

4.It has strong overload resistance, stable operation and high reliability.

|

Model |

ZS-630 |

ZS-800 |

ZS-1000 |

ZS-1200 |

ZS-1500 |

|

Capacity (kg/h) |

600-800 |

800-1000 |

1200-1500 |

1500-2000 |

2000-2500 |

|

Main motor (kw) |

5.5 |

7.5 |

7.5 |

11 |

15 |

|

Air iock power |

1.1 |

1.5 |

2.2 |

2.2 |

2.2 |

|

Weight (kg) |

2600 |

2800 |

3800 |

4500 |

5000 |

|

Diameter of roller (cm) |

63 |

80 |

100 |

1200 |

1500 |

|

Length of roller (cm) |

90 |

100 |

100 |

120 |

120 |

|

Total length (cm) |

90+40 |

100+50 |

100+50 |

120+60 |

120+80 |

|

Wood waste consumption (kg/h) |

15-20 |

20-25 |

30-40 |

40-50 |

50-60 |

|

Moisture before drying(%) |

40-70 |

40-70 |

40-70 |

40-70 |

40-70 |

|

Moisture after drying (%) |

13-18 |

13-18 |

13-18 |

13-18 |

13-18 |

1. Are you a manufacturer or trading company?

We are manufacturer with 20 years' experience.

2. How long is your leading time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment. For regular customers, more flexible payment ways are negotiable

4. How long is the warranty? Does your company supply the spare parts?

One year warranty for main machine, wearing parts will be provided at cost price

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you design and set up a complete production line and offer relative professional advice.

6. Can we visit your factory?

Sure, you are warmly welcome to visit.